Industrial Pressure Sensor DIN43650 Pressure Gauge for Liquid Gas Steam

Product Overview: HPM 1805 pressure transmitter adopts silicon piezoresistive sensor as signal measuring element which h;

Basic Info.

| Model NO. | HPM1805 |

| Certification | ISO |

| Customized | Customized |

| Output | 4~20mADC 1~5VDC 0.5~0.45VDC |

| Working Temp | -30~85 |

| Supply | 5VDC 24VDC |

| Shell Material | 304, 316L |

| Protection of Shell | IP65 |

| Storage Temp | -20~100 |

| Pressure Reference | Gauge, Absolute, Sealed Gauge |

| Overpressure | 1.5 times the full scale |

| Accuracy | 0.25%F.S. |

| Pressure | -100kpa...0~0.01...100MPa |

| Sensor Type | Pressure Sensor |

| Transport Package | Carton |

| Trademark | HangJia |

| Origin | China |

| HS Code | 90262010 |

| Production Capacity | 50000 Pieces / Year |

Product Description

Product Overview:HPM 1805 pressure transmitter adopts silicon piezoresistive sensor as signal measuring element which has high stability and reliability, and it undergoes wide temperature range performance compensation through automatic calibration process. The signal circuit is located in the stainless steel housing and it converts the sensor signal into a standard current signal for output. The whole product has undergone strict testing and aging, and its performance is stable and reliable. The product adopts all-stainless steel structure and has waterproof and breathable design. It is easy to install and suitable for long-term use in harsh environments. It is widely used in equipment matching, water supply, gas supply, chemical industry, metallurgy and hydrology industries, etc.

Features:

- All stainless steel construction

- Suitable for liquid, gas and steam, strong versatility

- Reverse polarity protection and transient overcurrent and overvoltage protection which meet EMI requirements

- Wide measuring range, perfect for gauge pressure, absolute pressure and sealed gauge pressure

- Waterproof and breathable treatment, protection grade IP65

- On-site display optional

- Strong anti-interference, long-term stability

Parameters:

| Measuring Medium | Liquid, Gas or Steam |

| Pressure Range | -100kPa…0~0.01…100MPa |

| Overload | 1.5 times pressure range of full scale |

| Pressure Type | Gauge, Absolute or Sealed Gauge |

| Accuracy | ±0.25%FS |

| Long-term Stability | ±0.2%FS/year |

| Temperature Coefficient of Zero | ±0.03%FS/ºC(Reference 25ºC) |

| Temperature Coefficient of Full Scale | ±0.03%FS/ºC(Reference 25ºC) |

| Working Temperature | -30~85ºC(General type);-20~60ºC(Explosion-proof type);-10~60ºC(Intrinsic safety type) |

| Storage Temperature | -40~100ºC |

| Supply Voltage | 5VDC 24VDC |

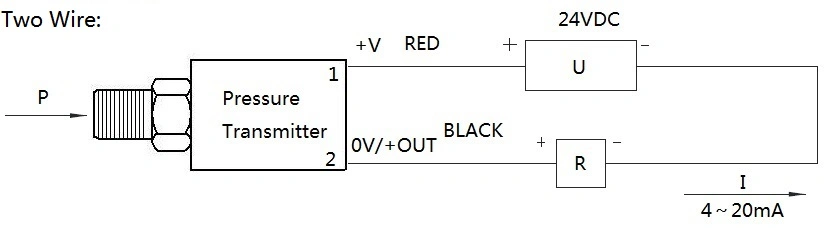

| Output Signal | Two-wire 4~20mADC Three-wire Voltage |

| Resistance | 100MΩ,500VDC |

| Insulation Resistance | 100MΩ,500VDC |

| Protection of Shell | IP65 |

| Electrical Connection | DIN43650 |

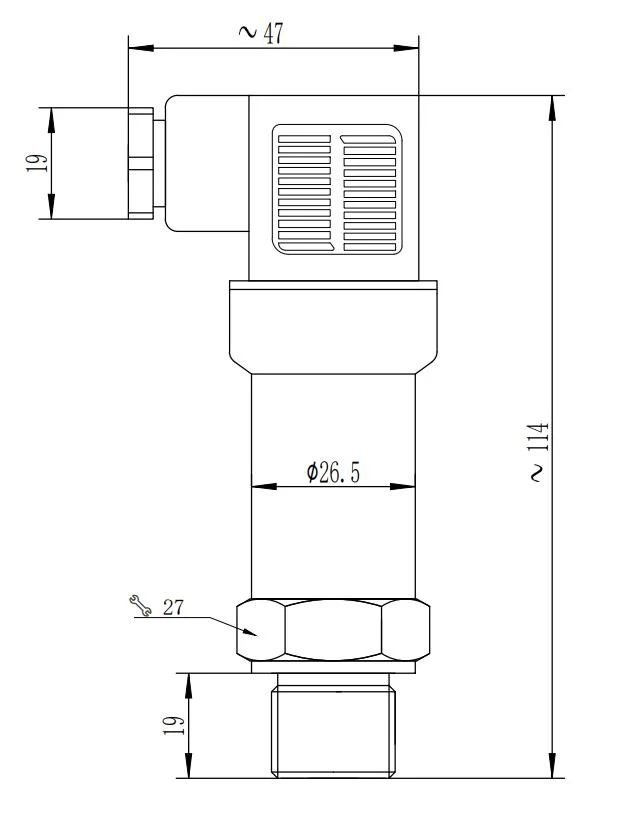

Structure Drawing:

Electrical Connection:

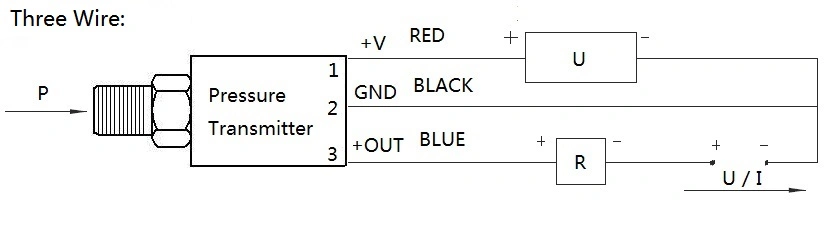

Application:

Ordering Guide:

| Item No. | Type | |||||||

| HPM1805 | Pressure Transmitter | |||||||

| Pressure Range | Measuring Range | |||||||

| (0~X)kPa | Fill out X directly | |||||||

| Code | Output Signal | |||||||

| B1 | (4~20)mA | |||||||

| B2 | (0~10)mA | |||||||

| B3 | (0~10)V | |||||||

| B4 | (0~5)V | |||||||

| B5 | (1~5)V | |||||||

| B6 | (0.5~4.5)V | |||||||

| Code | Thread Spec | |||||||

| P1 | M20×1.5 | |||||||

| P3 | G1/4 | |||||||

| P4 | G1/2 | |||||||

| Code | Electrical Connection | |||||||

| C1 | DIN43650 | |||||||

| Code | Structure&Material | |||||||

| Diaphragm | Interface | Shell | ||||||

| M1 | 316L | Stainless Steel | Stainless Steel | |||||

| M1A | 316L | 316L | Stainless Steel | |||||

| M1B | 316L | 316L | 316L | |||||

| M2 | Titanium | Titanium | Titanium | |||||

| M3 | Tantalum | Customized | Customized | |||||

| M4 | Hastelloy | Customized | Customized | |||||

| Code | Additional Functions | |||||||

| G | Gauge Pressure(Default) | |||||||

| A | Absolute Pressure | |||||||

| S | Sealed Gauge Pressure | |||||||

| HPM1805 | (0~100)kPa | B1 | P1 | C1 | M1 | GV1 | ||

Related Products:

Certification:

FAQ:

1. Q: Are you manufacturer or trading company?

A: We are manufacturer which focuses on sensor for 10 years.

2. Q: What's your quality control system?

A: MC, ISO9001, CE Certificated.

3. Q: What is the warranty of your products?

A: Our warranty time is 18 months after shipment.

4. Q: What is lead time of your product? A: Normally, our factory lead time is within 10~15 working days for products without customization. You can also check lead time detail with our sales depending on different items.

5. Q: Do you provide customized products? A: Yes, we can laser mark your logo on products; OEM and ODM customization are welcomed.

6. Q: What is your MOQ? A: We have no MOQ limit, small quantity order is acceptable.

7. Q: What's the transport? A: Express such as DHL, FedEx, TNT, UPS for freight prepaid; and we can also use your own courier account to do the freight collect. For more goods we can arrange by air or by Sea.

8. Q: What is your terms of payment ? A: We could accept T/T, Paypal, WU.

You may also like

Send inquiry

Send now